KEY FACTS

WE WILL SUPPORT YOU

WITH OUR KNOW-HOW

IN TESTING TECHNOLOGY

We simulate

using FE simulations in the fields of

static, dynamic and strength analysis

for your product development

We validate

your railway wheelsets and

crankshafts to help with your

product releases

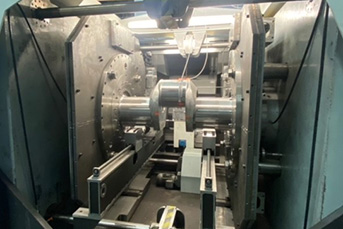

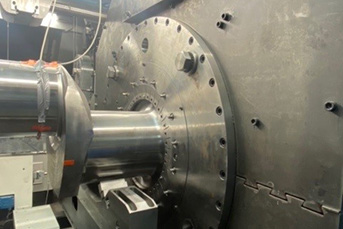

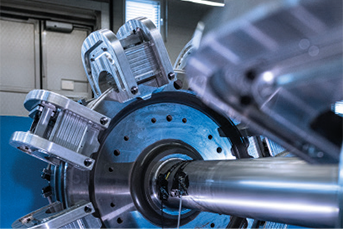

SINUSJET GEN 3.0

Prisma Power Oscillator

SINUSJET GEN 3.0

Railway Application

For the first time in the world, our unique SINUSJET GEN 3.0 is capable of applying bending and torsional load even at the same time.

The real validation of the theoretical design of safety-relevant parts, such as railway wheelsets, requires a careful and innovative execution of the tests and can be easily and tailormade implemented by the new SINUSJET GEN 3.0.

Testing of the whole

railway wheelset

Fast and convenient

sample change

No foundation

required

Maintenance free

at low energy

consumption

Low noise &

vibration

in operation

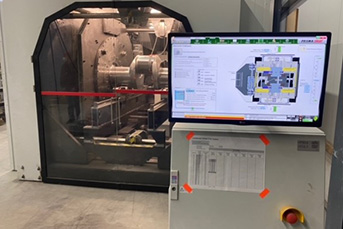

SINUSJET LIGHT

Railway Application

SINUSJET LIGHT is the bending-focused lightweight edition of our innovative SINUSJET GEN 3.0 testbed.

Develop and qualify your wheelset to meet all the current wheel and shaft standards (such as EN 13103-1, EN 13979-1 or EN 13260). Thanks to the modular design of SINUSJET LIGHT, you can decide to upgrade the testbed later to a fully functional SINUSJET GEN 3.0 to meet even more future requirements.

Testing of the whole

railway wheelset

Fast and convenient

sample change

No foundation

required

Maintenance free

at low energy

consumption

Low noise &

vibration

in operation

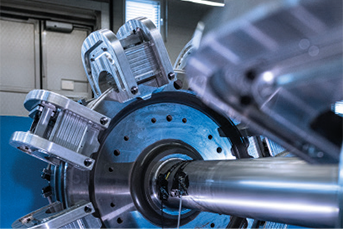

SINUSJET LEF

Large Engine Family

To master the future requirements in large engine construction, such as the increase in performance and efficiency with simultaneous lightweight design, these must be validated by innovative tests after careful theoretical FE layout. These consequently continual tests of component safety and product qualification may be carried out uniquely with our SINUSJET LEF series.

Crankshaft

< 500 mm

Torsion moments

< 4000 kNm

Compact design

PLUG & PLAY

Maintenance free

at low energy

consumption

Low noise &

vibration

in operation